Lawsuit Claims Janitor's Actions Destroy $1Million Worth Of 20 Year School Research After Turning Off Freezer Due To Annoying Alarms

A university lawsuit claims janitor's actions destroy $1million worth of 20 year school research. The Rensselaer Polytechnic Institute in upstate New York has filed the lawsuit against cleaning company Daigle Cleaning Systems Inc. after a janitor, employed by the company, allegedly turned off a freezer, resulting in the destruction of more than 20 years of valuable research.

Author:Black Crystal Reviewer:Maxwell CanvasJun 29, 202318.4K Shares245.8K Views

A university lawsuit claims janitor's actions destroy $1million worth of 20 year school research. The Rensselaer Polytechnic Institute in upstate New York has filed a lawsuit against cleaning company Daigle Cleaning Systems Inc. after a janitor, employed by the company, allegedly turned off a freezer, resulting in the destruction of more than 20 years of valuable research.

Lawsuit Claims Janitor's Actions Destroy $1Million Worth Of 20 Year School Research

The incident occurred in 2020, when the janitor, who is not being sued personally, heard multiple "annoying alarms" and decided to flip the circuit breakers, unknowingly shutting off power to the freezer.

The freezer contained critical research materials, including cell cultures and samples, which were highly sensitive to temperature fluctuations. Even a small change of three degrees Celsius could cause catastrophic damage.

According to the lawsuit filed with the Rensselaer County Supreme Court, the university asserts that a small fluctuation in the freezer's temperature triggered the alarms, which should have been heeded as a warning sign.

Rensselaer Polytechnic Institute does not hold the janitor responsible but instead, places blame on Daigle Cleaning Systems for failing to adequately train and supervise their personnel. The university claims that the cleaning company's negligent and careless supervision led to the damage of the research materials.

While the cleaning company is yet to respond to the allegations, Michael Ginsberg, the attorney for Rensselaer gave a statement.

“„We don't believe there was any nefarious conduct (on the) part of the cleaning company. This was a result of human error. The core of the case, however, is that the cleaning company failed to adequately train its personnel. A cleaner should be trained to not attempt to remedy an electrical issue.- Michael Ginsberg, Attorney of Rensselaer Polytechnic Institute

The lawsuit highlights the importance of maintaining a consistent temperature of - 80 degrees Celsius for the cell cultures and specimens stored in the freezer. The university asserts that the alarms would sound if the temperature deviated by just three degrees, reaching either - 78 degrees or decreasing to - 82 degrees.

On or around September 14, 2020, K.V. Lakshmi, a professor, and director of the Baruch '60 Center for Biochemical Solar Energy Research at Rensselaer, noticed that the freezer's temperature had risen to - 78 degrees, triggering the alert.

Despite this, Lakshmi and her team believed the cell samples would remain safe until emergency repairs could be carried out. To prevent any accidental disruption, a safety lock box was placed around the freezer's outlet and socket, and a warning sign was posted.

“„THIS FREEZER IS BEEPING AS IT IS UNDER REPAIR. PLEASE DO NOT MOVE OR UNPLUG IT. NO CLEANING REQUIRED IN THIS AREA. YOU CAN PRESS THE ALARM/TEST MUTE BUTTON FOR 5-10 SECONDS IF YOU WOULD LIKE TO MUTE THE SOUND.- Warning posted on the freezer

However, on September 17, the janitor, hearing what he considered to be "annoying alarms," attempted to help by flipping the circuit breakers. Unfortunately, he mistakenly turned them off instead of on, resulting in the freezer's temperature rising to - 32 degrees Celsius.

The following day, research students discovered the freezer turned off, and despite their efforts to salvage the research, a significant portion of the cell cultures had been compromised, destroyed, and rendered unsalvageable. The lawsuit claims that more than 20 years of valuable research were lost as a result of this incident.

Rensselaer Polytechnic Institute is seeking damages of over $1 million, as well as legal fees, from Daigle Cleaning Systems. The case raises questions about the importance of proper training and supervision in situations where research materials of great significance are involved.

Best Practices For Maintenance Protocols And Training In Research Facilities

Research facilities are home to invaluable scientific work, often involving years, if not decades, of dedicated research. Tragically, accidents can occur, leading to significant damage, loss of data, and sometimes even jeopardizing the safety of researchers and personnel.

It is crucial for research institutions to implement robust maintenance protocols and provide comprehensive training to minimize the risk of such incidents. Let's get to know the best practices for mitigating research facility accidents, focusing on maintenance protocols and training.

Importance Of Maintenance Protocols

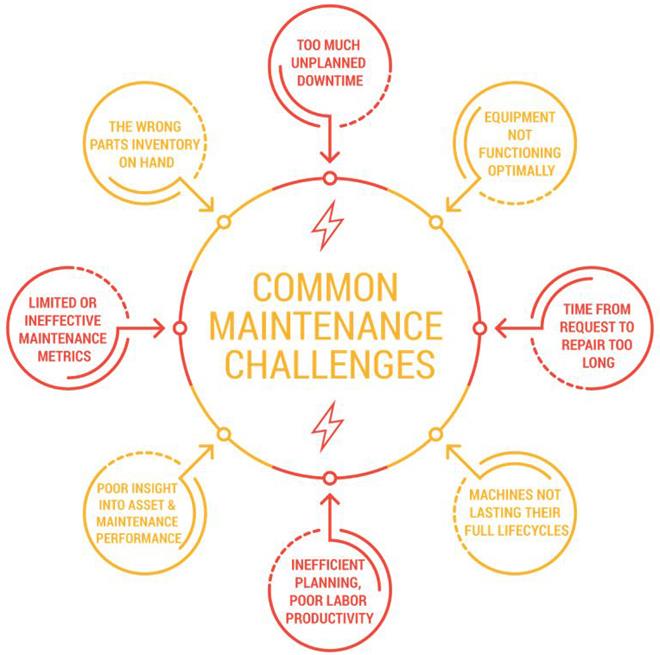

Maintenance protocols play a pivotal role in ensuring the smooth operation and longevity of research facilities. By adhering to a structured maintenance plan, potential risks and issues can be identified early on, preventing costly accidents and minimizing downtime. Here are some key considerations when developing maintenance protocols:

- Regular Equipment Inspections - Establish a schedule for routine inspections of critical equipment, such as freezers, incubators, and laboratory machinery. These inspections should encompass thorough checks for malfunctioning components, potential leaks, and any deviations from recommended operating parameters.

- Calibration and Performance Verification -It is crucial to periodically calibrate and verify the performance of sensitive equipment to ensure accuracy and reliability. Temperature-controlled devices, pressure gauges, and measuring instruments should undergo regular calibration to maintain their precision.

- Emergency Response Planning - Develop comprehensive emergency response plans tailored to the specific needs of the research facility. Identify potential risks, establish emergency contact information, and ensure the availability of emergency supplies and equipment, such as fire extinguishers and first aid kits.

Training For Facility Maintenance Personnel

Proper training is the foundation of a safe and well-maintained research facility. Maintenance personnel should receive thorough training to equip them with the necessary knowledge and skills to identify potential hazards, perform routine maintenance tasks, and respond effectively to emergencies.

Here are some essential aspects of training programs for facility maintenance personnel:

- Equipment-Specific Training -Provide comprehensive training on the specific equipment used within the research facility. This should include detailed instructions on proper operation, maintenance procedures, troubleshooting techniques, and safety precautions. Training sessions should be conducted by qualified experts or manufacturers' representatives.

- Safety Protocols and Hazard Identification -Educate maintenance personnel about the importance of safety protocols and hazard identification. Train them to recognize potential risks, such as electrical hazards, chemical spills, and biohazardous materials, and provide guidelines on how to handle these situations safely.

- Emergency Response Training -Conduct regular emergency response drills to ensure that maintenance personnel are well-prepared to handle unforeseen events. Simulated scenarios can help them develop the necessary skills to respond efficiently and effectively in high-pressure situations.

Collaboration And Communication

Maintaining a safe research facility requires effective collaboration and communication between various stakeholders, including researchers, facility managers, and maintenance personnel. Open lines of communication enable the swift reporting of potential issues, timely maintenance requests, and efficient coordination of activities. Consider the following strategies to enhance collaboration:

- Reporting Systems -Establish a user-friendly reporting system that allows researchers and personnel to easily submit maintenance requests or report any safety concerns. Encourage prompt reporting of issues, ensuring that they are promptly addressed and resolved.

- Regular Meetings -Conduct regular meetings involving researchers, facility managers, and maintenance personnel to discuss ongoing maintenance requirements, address any recurring issues, and provide updates on facility safety. This forum can facilitate the sharing of knowledge and foster a culture of collaboration.

- Cross-Training Opportunities -Encourage cross-training initiatives where researchers and maintenance personnel can learn from each other's expertise. This cross-pollination of knowledge can lead to a better understanding of equipment functionality, early identification of potential issues, and improve overall facility safety.

Implementing Comprehensive Maintenance Protocols

To mitigate the potential for accidents in research facilities, institutions must adopt comprehensive maintenance protocols. These protocols should cover various aspects, including equipment maintenance, environmental controls, and safety measures. Here are some key considerations when establishing maintenance protocols:

- Regular Equipment Inspections -Regular inspections of research equipment and facilities are vital to identify potential issues before they escalate into major problems. This includes checking electrical connections, monitoring temperature and humidity levels, and assessing the overall condition of the equipment. By implementing a proactive maintenance schedule, facilities can address potential hazards and minimize the risk of accidents.

- Calibration and Validation -Accurate calibration and validation of equipment are critical to maintaining consistent and reliable research outcomes. Regular calibration checks ensure that instruments provide accurate measurements, reducing the possibility of errors or incorrect data interpretations. These checks should be conducted by trained technicians using calibrated reference standards.

- Emergency Response Plans - Every research facility should have a well-defined emergency response plan in place. This includes clear procedures for handling equipment malfunctions, power outages, and other critical incidents. All personnel should be familiar with these plans and receive training on their roles and responsibilities during emergencies. Regular drills and simulations can further enhance preparedness and ensure efficient and coordinated responses.

People Also Ask

What Are The Best Practices Of Facilities Management?

Effective facilities management is crucial for maintaining a well-organized and efficient workplace. By incorporating the following best practices, organizations can optimize their facility operations and achieve greater productivity:

- Centralize facility management through software to streamline operations and improve coordination.

- Stay abreast of technology advancements and leverage the Internet of Things (IoT) to enhance facility functionality.

- Collect comprehensive information about facility needs, resources, and performance to make informed decisions.

- Recognize and capitalize on emerging trends in facilities management to stay ahead of the curve.

- Automate repetitive facilities processes to increase efficiency and reduce manual workload.

- Make budgeting a priority to allocate resources effectively and ensure optimal facility performance.

Which Maintenance Practice Is Done To Ensure That Facilities And Equipment Are Operating Safely And Efficiently?

Corrective maintenance refers to the necessary repairs carried out to restore equipment to its proper functioning condition or service. It can be either planned or unplanned in nature.

What Is The Best Practices To Follow When Using Maintenance Equipment?

To ensure optimal performance and longevity of maintenance equipment, it is important to adhere to best practices. By following these recommendations, organizations can enhance equipment reliability and minimize downtime:

- Maintain Detailed Records- Keep comprehensive records of equipment maintenance activities, including repairs, inspections, and servicing. This documentation helps track maintenance history, identify recurring issues, and plan future maintenance tasks effectively.

- Adhere to Manufacturer's Recommended Maintenance Schedules - Follow the maintenance schedules and guidelines provided by the equipment manufacturer. These recommendations are designed to optimize equipment performance and prevent premature wear and tear.

- Regularly Inspect the Equipment - Conduct routine inspections of the equipment to identify any signs of damage, malfunction, or wear. Promptly address any issues or abnormalities discovered during inspections to prevent further deterioration or potential breakdowns.

- Involve Operators or Drivers- Engage the operators or drivers of the equipment in the maintenance program. Encourage them to report any observed issues or abnormalities promptly. Their input and feedback can provide valuable insights into the equipment's performance and aid in the early detection of potential problems.

- Inspect the Surrounding Space - Ensure that the area surrounding the equipment is clean, organized, and free from any hazards or obstructions. Regularly inspect the workspace to identify potential risks or safety concerns that could impact equipment operation or maintenance procedures.

By following these best practices, organizations can optimize equipment maintenance, minimize unplanned downtime, and maximize the overall efficiency and safety of their operations.

Conclusion

In conclusion, the lawsuit claims janitor's actions destroy $ 1 million worth of 20-year school research underscoring the critical need for robust maintenance protocols and comprehensive training programs in research facilities. Inadequate maintenance protocols can have severe consequences, jeopardizing valuable experiments and data integrity.

By implementing comprehensive maintenance protocols that include regular equipment inspection, environmental monitoring, and emergency response plans, research facilities can minimize the risks of accidents and ensure the continuity of scientific progress. Additionally, providing proper training to personnel on equipment operation, safety procedures, and emergency preparedness is crucial for maintaining a safe and efficient research environment.

Collaborative efforts and accountability among all stakeholders are paramount to mitigating research facility accidents and preserving the invaluable work conducted within these institutions. The incident serves as a reminder of the importance of vigilance and investment in maintaining the integrity and longevity of scientific research.

Jump to

Lawsuit Claims Janitor's Actions Destroy $1Million Worth Of 20 Year School Research

Best Practices For Maintenance Protocols And Training In Research Facilities

Importance Of Maintenance Protocols

Training For Facility Maintenance Personnel

Collaboration And Communication

Implementing Comprehensive Maintenance Protocols

People Also Ask

Conclusion

Black Crystal

Author

Black Crystal is a captivating writer who finds inspiration in the quiet corners of the street and the mysterious depths beneath bridges. With a penchant for the night, she crafts enchanting tales that explore the uncharted realms of the human experience. Embracing the darkness as her muse, Black Crystal's evocative prose and haunting imagery transport readers into a world where secrets whisper and dreams take shape.

Her writing defies categorization, inviting readers to uncover the magic hidden within the shadows and embrace the enigmatic beauty of her nocturnal narratives. Step into her realm, where the written word dances with ethereal grace, and immerse yourself in the captivating stories she weaves.

Maxwell Canvas

Reviewer

Maxwell Canvas, a charismatic and fearless crypto evangelist, defies conventions and blazes a trail in the realm of digital currencies. With his unique physique serving as a symbol of resilience, he challenges societal norms and proves that true expertise transcends appearances. Against a backdrop of a blurred and ever-shifting market, Maxwell's work becomes a masterpiece, painting a vivid picture of knowledge and inspiration.

With unwavering passion, Maxwell empowers others to embrace the transformative potential of blockchain technology. His captivating presence and unyielding dedication captivate audiences, turning skepticism into curiosity and igniting a spark of interest in the world of cryptocurrencies. Maxwell Canvas stands as a visionary force, leaving an indelible mark on the crypto landscape, inspiring others to explore decentralized possibilities and embrace a future of innovation and financial empowerment.

Latest Articles

Popular Articles